It is my understanding that most of the people working on it are more concerned with getting it good enough, and the bulk of their development energy on 3d printing slicing engines. It's a cool idea, but it's toolchain has always been sub par. It is really a product of open source 3d printers who were seeking a way to describe complex 3d objects, reliably version them, and then spread them around the internet.

It is also focused on supporting Volumetric modeling of 3d objects, rather than simply being CSG based like most CAD software, even though it takes that approach for simple objects. Having 3D objects described in a text based environment is the idea. Proprietary and opaque file format that no other product outside of the AutoDesk ecosystem can read, lousy at reading things created with other softwares. It is definitely not up to par with Fusion's engine.ħ) Fusion is lousy at talking to the rest of the ecosystem. In particular, it's a complete black box: there is exactly zero guarantees that your carefully crafted model will still work 10 years down the road.Ħ) Freecad's UI is basically a nightmare and the CAD engine (the terminolgy in the CAD world for some reason it is called the "kernel") is the same that cadquery uses, and it's an old and clunky NURBS engine called OpenCascade (if I'm not mistaken). Worse, you are basically at the mercy of the vendor. Cadquery is slowly getting to the sweet spot OpenScad occupies, but it's not there yet.ĥ) Fusion is proprietary, closed-source and costs money. Blender is way better for this use case.Ĥ) If you are a programmer and enjoy building truly parametric models, as in: models that you can build with scripts and Makefiles, then neither freecad nor fusion are a fit.

Also, if your model starts to become really complex ( lots of boolean), OpenSCAD becomes very slow and eventually unusable, even with the change described by the OP.ģ) If you need to model organic shapes neither freecad, fusion or OpenSCAD are unusable.

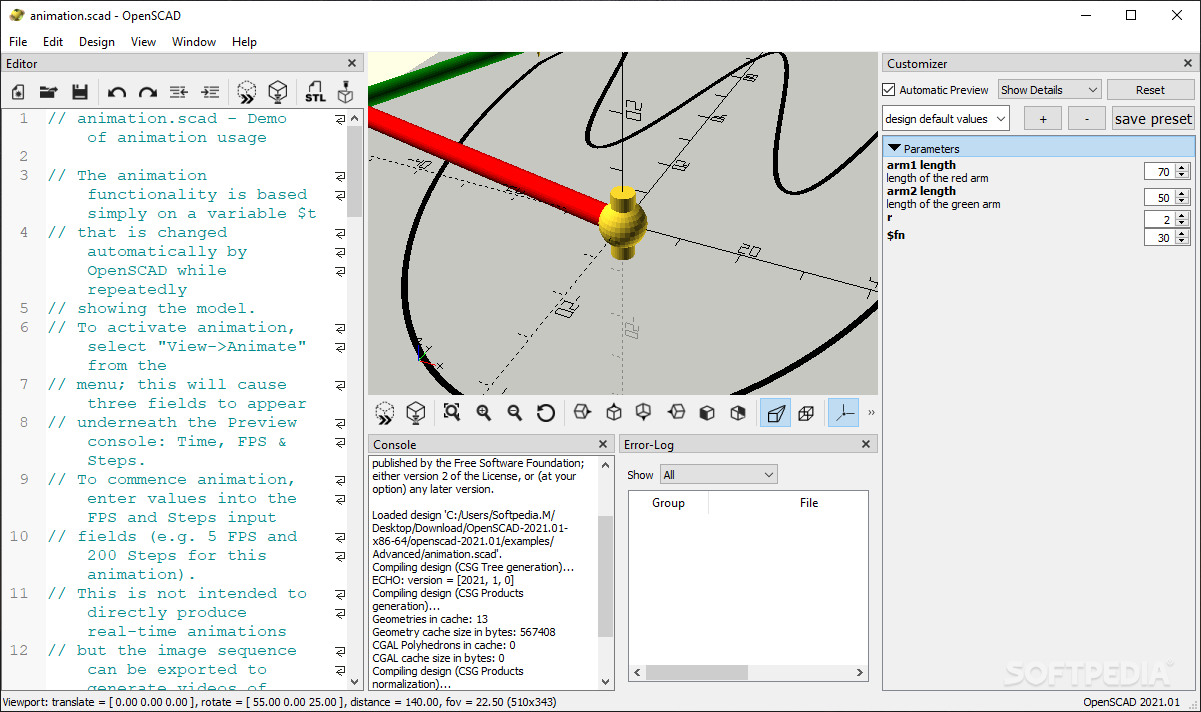

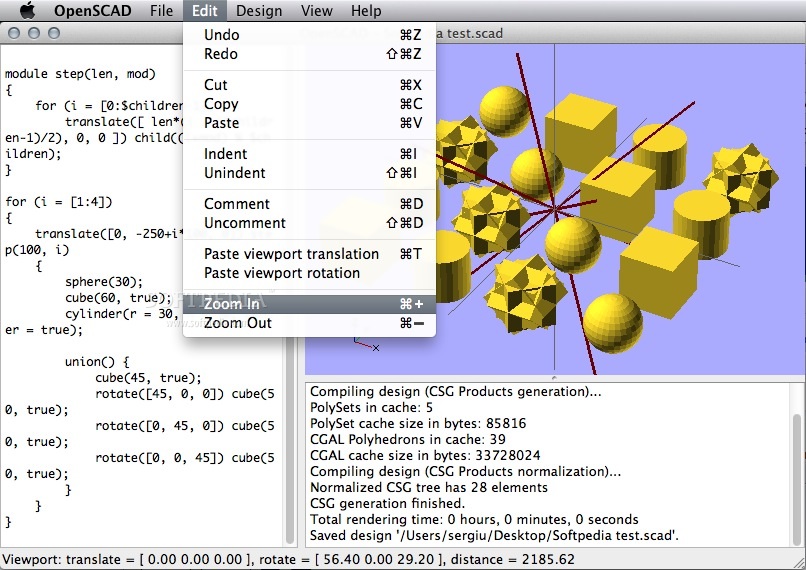

OPENSCAD FOR LOOP HOW TO

Unless you don't know how to code, in which case it's unusable.Ģ) When you start to need chamfers and fillets, OpenSCAD simply doesn't work and Fusion is by far the superior solution. > Then I moved to Fusion and from that point I think that I’ve found a sweet spotġ) It depends on the kind of object you want to model: for simple, geometric shapes, OpenSCAD is by far the best choice.

OPENSCAD FOR LOOP SOFTWARE

But for complex models it can’t really hold up to the more traditional parametric modeling software (yet) I too like OpenSCAD the best and often find myself more productive in it than other pieces of software, especially for simple models. Slicers these days are actually quite good at repairing geometry but even with a moderately complex part produced by boolean operations (in my case it was often one that required subtraction of cylinders across multiple pieces of an object) I found OpenSCAD’s output to produce some bizarre issues with geometry that even the slicer could not repair very well. But there is also still not a guarantee that the output of those boolean operations is actually a manifold object. It is not at all trivial in OpenSCAD.Īnother example of OpenSCAD’s limitations is the render time for parts produced by boolean operations which this change purportedly helps a lot with. This seemingly simple operation is rather trivial to do in FreeCAD and Fusion 360. One recent example is that I was designing a part for injection molding and I needed to add a draft angle to the part. I prefer the style of OpenSCAD but I’ve found that there are certain things that the software just is either really hard to achieve or incapable of doing entirely.

0 kommentar(er)

0 kommentar(er)